Rollpack

Probably the only Roll Packing machine that allows so many springs to be loaded into a truck or a container!

The Roll Packing machine packs bulky innerspring units of up to 200cm in width into easy-to-ship and easy-to-open compressed rolls. The Rollpack RL2000 offers convenient, fast, safe and low cost baling of innersprings for mattresses and upholstery.

Click here to download our Rollpack RL 2000 Brochure

Click here to download our Rollpack RL 2000PRE Brochure

Click here to download our Rollpack RL 2000PRE/VS Brochure

- This machine carried CE certification.

RL2000 incorporates a hydraulic ejector system giving 80% faster ejector time of 35 seconds and an overall 20% faster working cycle time compared to conventional screw-type ejection operated Rollpacking machines. The spring units are compressed and wrapped together using special kraft paper or polyethylene film (or other suitable material) on a mandrel.

The level of compression can be adjusted by a pneumatically controlled pressure roller and paper tension to suit any strength of spring. Up to 20 units can be wrapped in a roll with the number depending on the size and height of the spring unit, the thickness of the wire and whether flat border frame is attached. Once the paper is cut and secured, the roll is automatically drawn out from the mandrel by means of a hydraulic ejector and the bale is ready for shipment or compact storage. - Maximum width of spring units to be packed: 200 cm

Maximum height of coils to be packed: Bonnell 16cm & Pocketed 22cm

Type of spring units:

Bonnell, continuous, pocketed etc., with or without flat steel strip border frame. For spring units with height greater than 16cm, the use of 2-ply wrapping paper is recommended.

Wrapping Material:

Extensible kraft paper is most commonly used. Other material such as plastic film and PP cloth can also be used. Maximum roll diameter is 80cm and bore diameter is 75mm. One or two rolls of paper can be used depending on the type and size of spring units being used.

Wire of coils:

Due to adjustable pressure available on the pressure roller, practically any coil wire diameter can be used (as long as the paper is strong enough).

Mandrel diameter:

215mm (standard). 250mm & 280mm (optional) can also be used to suit different types and heights of spring units and flat border frame.

Maximum Roll diameter:

Absolute maximum diameter 70cm. A warning signal is given when the roll exceeds the diameter of 65 cm. Recommended diameter 60cm so that 4 rolls will fit exactly a container's width and height.

Electrical power consumption:

Maximum 7.5kW

Compressed air supply:

About 6kg/cm2, with a consumption of less than 0.01m3 per roll (per cycle). - Higher ejection power to achieve a production rate of 8-10 bales per hour

- Additional shafts enable the machine to roll pack spring units of exceptionally greater height

- Photoelectric sensors at knee level to avoid accidents

- The machine is supplied complete with feeding table on rails

- The weight of the machine is 3450kg and can be delivered in a 20' container.

- With pre-compression feeding table

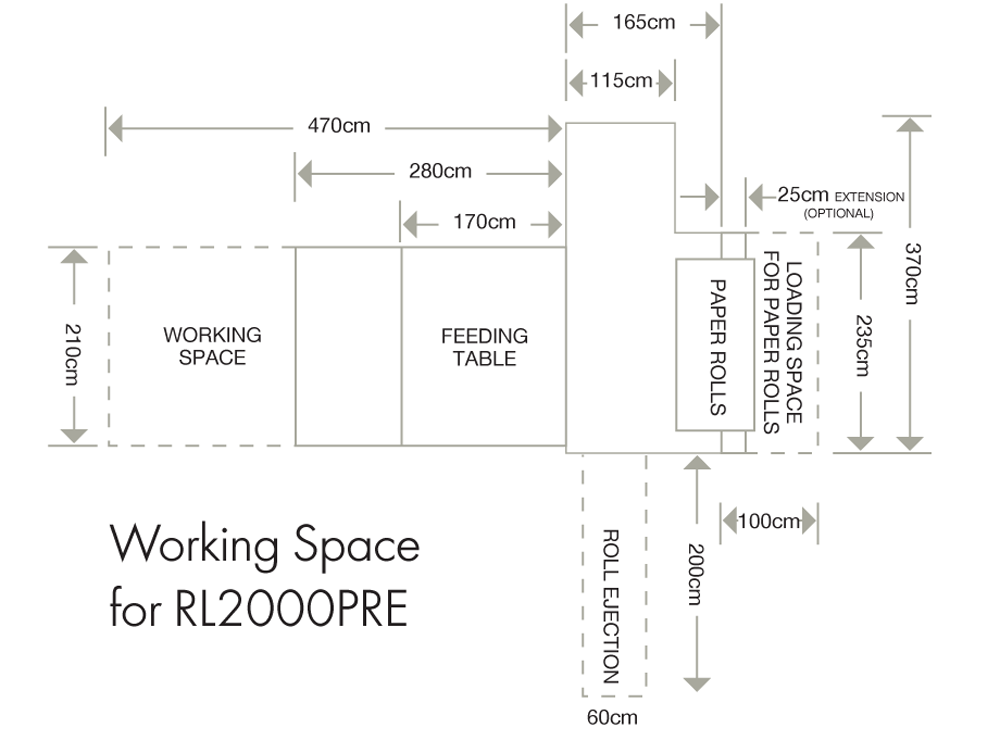

The RL2000PRE is the solution to roll packing very tall spring units, up to 22cm height. Using one operator even for very large and heavy spring units, it is Suitable for all kind of spring units, Bonell, pocketed etc. No additional paper is needed to compress the unit and no operator skills are needed for roll packing. It is fast, easy to operate, no training, minimal installation and it avoids possible damage during roll packing.

The springs are pre-compressed and then fed at the correct angle and height into the machine, between the main mandrel and compressing roller. The machine features all facilities of the other models RL2000EH and RL2000A. Automatic paper feeding on starting, extended bar holding the paper on the mandrel, automatic strapping etc.

- Fully computerised feeding table synchronised with the rolling feeding speed

- Height table adjustment to optimise the correct feeding angle in the machine

- Optional paper extension stand, to enable the use of 2 additional paper rolls (or other wrapping material), or reels of up to 120cm in diameter

- Optional Automatic Paper Cutting system

- Optional touch PLC screen

- Optional automatic spring units counter

- Mandrel standard diameter 240mm. Other diameters are available on demand

- Weight: Main machine 3650 kg, Feeding table 650 kg, Additional paper stand 300 kg (optional)

- With pre-compression feeding table and vertical / horizontal stacking

The RL2000PRE/VS is the solution to roll packing very tall spring units, up to 25cm height pocketed and 16cm bonnel units. Using one operator even for very large and heavy spring units, it is. No additional paper is needed to compress the unit and no operator skills are needed for roll packing. It is fast, easy to operate, no training, minimal installation and it avoids possible damage during roll packing. The machine has the facility to be operated in an automatic, semi-automatic or manual mode.

The springs are pre-compressed and then fed at the correct angle and height into the machine, between the main mandrel and compressing roller. The machine features all facilities of the RL2000PRE version with automatic paper feeding on starting, extended bar holding the paper on the mandrel, automatic strapping etc.

- Fully computerised feeding table synchronised with the rolling feeding speed

- Height table adjustment to optimise the correct feeding angle in the machine

- Touch PLC screen

- Automatic strapping with adhesive tape

- Optional paper extension stand to enable the use of 2 additional paper rolls (or other wrapping material), or reels of up to 120cm in diameter

- Optional Automatic Paper Cutting system

- Optional automatic spring units counter

- Mandrel standard diameter 240mm. Other diameters are available on demand

- Weight: 4500 kg, Additional paper stand 300 kg (optional)

The new upgraded Roll Packing machine RL2000PRE/VS has the option to deliver the bales / rolls on a standing position either on the floor or pallet. It can also deliver the rolls horizontally to be picked up by a forklift. - CE Certificate of safety:

The machine is protected with Safety guards, interlocks, sensors, accident safety devices, emergency Stops and head on collision Stop giving a safe operation.

Safety devices:

Safety guards, interlockings, sensors, an accidental emergency STOP and a "Head Collision" STOP give an extra safe operation.

Operation:

Automatic reverse and reset of the machine on ejection cycle.

Fully computerized. All logic circuits are controlled by a PLC (Programmable Logic Controller) giving additional safety features, flexibility and making the process operator friendly.

A motor inverter provides a fully variable speed capability, keeping the rolling/packing operation at a constant speed, independent of the diameter of the roll.

The rolling speed can be selected to suit the operator's pace, experience, type of spring unit, complexity, etc.

Pre-selected slow start of rolling gives the operator time to position the first unit. The machine stops automatically when the paper runs out or breaks.

Loading in container:

2200 innerspring units of 90x190x13cm and 2.0mm diameter wire (20 units packed in 60cm diameter roll), can be loaded inside a 20' container. -